Home » Tips & Advice » Forklift Safety Checklist

Forklift Safety Checklist

Forklift Safety Checklist

OSHA reports that on average there are 85 fatal accidents involving forklifts each year. On top of the fatalities there are 34,900 forklift accidents resulting in serious injury; and an additional 61,800 classified as non-serious.

The Industrial Truck Association estimates that there are about 856,000 forklifts in the country. That means that 11% of all forklifts will be involved in an accident. If you are in the manufacturing, construction or wholesale trades industry, the odds of your forklifts being involved in an accident are significantly higher. These three industries account for nearly 80% of all forklift related accidents.

It's important that companies realize that safety and safe working conditions contribute significantly to the bottom line and cannot be ignored. In addition of course, OSHA has set training and operational standards that if ignored, can carry hefty penalties.

What's the reason for forklift accidents? There are a number of factors that contribute to lift truck accidents on job sites, including:

- Lack of operator training

- Lack of job-specific accessories, attachments, and/or tools

- Lack of routine lift truck maintenance

- Operator performance pressure to complete jobs quickly

- Old/outdated forklift use

- Lack of management emphasis on safety

As we can see from the above most accidents are operator initiated. Attention spent in the selection, training, supervision, and operational support of these personnel is an excellent investment of company resources with a high ROI.

One of the ways to reinforce operator training and set the tone for safety is for the operator to conduct an inspection of his truck at the start of shift. Daily inspections are a good idea and it's the law. OSHA requires that these inspections be recorded and kept with the trucks records. They have a very specific checklist that they want to see and you can download a copy of it here.

The OSHA Safety Checklist is comprehensive but not terribly instructive. We've taken some of the more "mundane" checklist items and fleshed them out to help your drivers actually evaluate what they are looking at. We've divided these out into Pre-Operation and Operational lists to replicate the order in which an inspection would actually be conducted.

Pre-Operation Checklist Items:

- Backrest Guard. Make sure it is securely attached and functional

- Locking Keys. Make certain that they are present and locked

- Forks. Inspect the arms and heels for cracks. Deep cracks create a "no-go" condition as the fork may fail with a capacity load.

- Side Shift Cylinder. Look for dampness or any other sign of a leak

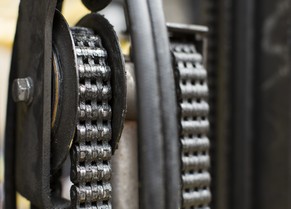

- Mast Chain. Should be tight with no slack

- Mast Frame. Should be straight with no indication of twisting. Check mast cylinders for dampness or leaking.

- Mast hoses. Look for cracks and signs of leaking

- Overhead Guard. Should be solidly secured in place

- Data Plate. Must be present and legible

- Seat. Should be in good repair, fixed in its position and the seat belt must be present and functioning

- Tires. For all tires look for excessive wear, chunks missing, tread condition. For pneumatic tires look for an under-inflated tire(s)

- Propane tank (if applicable). Check for rust and other signs of corrosion

- Batteries (if applicable). Make certain wires are clean and firmly attached. Occasionally check water level in random cell for lead acid batteries. Make certain all batteries are securely in place

Operational Checklist Items:

- Seat. Make certain it is adjusted so that you have comfortable access to pedals

- Instrument Cluster. Turn motor/engine on and check for red warning lights

- Lights. Test all lights including headlamps, front and rear indicator lamps, brake lights, "in operation flashing light" and reverse lights.

- Mast and Fork. Test lifting cylinder by raising the mast to its maximum height (always check for overhead clearance first) and lowering it. Tilt mast back and then tilt forward. Run the side shift all the way left and right.

- Steering. Place the truck in revers and then travel a short distance turning to the right. Repeat turning to the left. Control should be responsive. Look for fluid on the ground you just covered to determine if there are any leaks. If there is fluid present then you need to recheck all cylinders to locate the leak.

- Handbrake. Set the handbrake and apply a little power. The handbrake should hold the truck in place.

Redline Conditions:

- Any unusual sounds that arise once you start or add power to the engine/motor

- Evidence of fluid leaks. If you can identify where the leaks are you'll save the mechanic time

- Serious cracks in the forks or a twisted mast

- Serious damage to a tire or an under-inflated tire. When tires have different diameters they can create unbalanced conditions.

A company that follows this routine religiously will find that their rate of accidents and damaged materials will drop. Getting your operators intimately familiar with the machines they work with, and providing them the maintenance support they require, will have a positive impact on safety awareness and driver morale.